Kansas Farm Tour 2019

Note: This post contains affiliate links. As an Amazon Associate I earn from qualifying purchases.

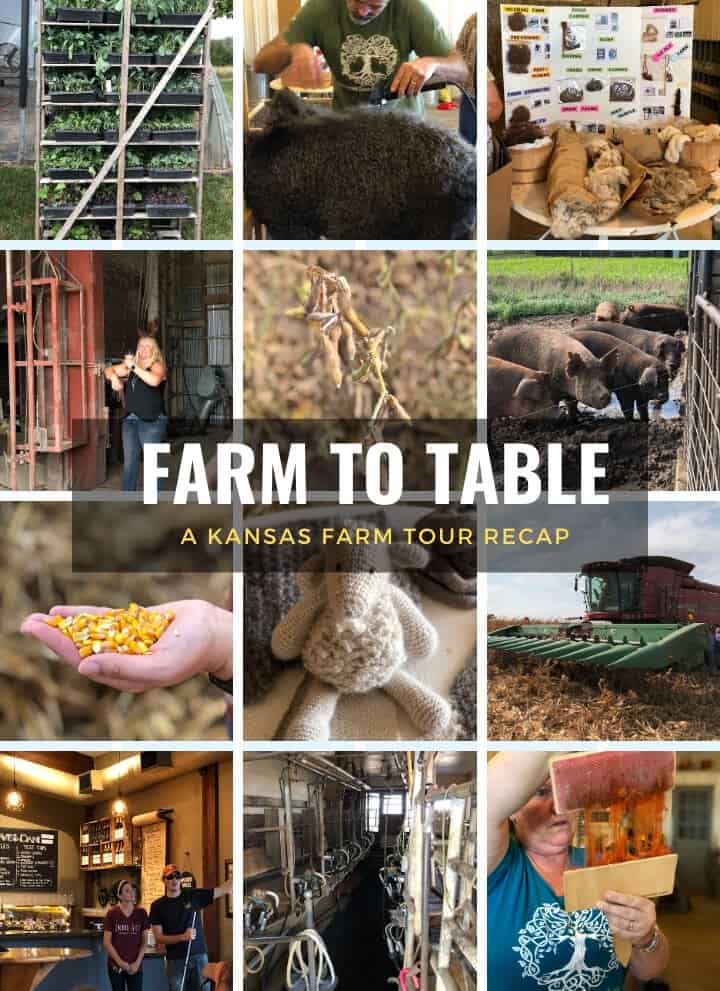

It is not very often that you get an opportunity to visit a host of farms and when I did, I seized it. I will be forever grateful to Kansas Farm Bureau and Kansas Soybean Commission for sponsoring the trip and this post. This article is a recollection of my fond memories from the trip and an attempt to showcase all the sweat and tears involved in agriculture.

This incredible Kansas farm tour took me and a bunch of other bloggers on a 3-day trip to 8 different farms. Join me as I share my experiences and learnings from each location.

Day 1 – Juniper Hill Farms, Good Pig Farm, and Liquid Art Winery

Juniper Hill Farms

Our first stop was in Lawrence, where we stopped by Juniper Hill Farms and met Scott Thellman. He is a first-generation farmer who decided to become one after being fascinated by cattle grazing on his parent’s farm. He started off by selling hay and now grows vegetables such as kale, Napa cabbage, turnips, spinach, Roma tomatoes, etc.

Here’s what I learned

- 90% of what is grown in Juniper Hill Farms is shipped within a 100-mile radius.

- It was interesting to learn that farmers like Scott also have to diversify their income. He does so by consulting, handling produce distribution for Amish farmers, and leasing freezer space for meat storage, to name a few.

- How hard it is to find labor – farming is a back-breaking job, and there is a high attrition rate.

- I realized how weather-dependent this industry is. For instance, because of a recent flood, they lost the ability to grow vegetables – a massive loss of $150K!

- While insurance exists for crop farming, it is a lot trickier compared to commodity farming.

- Last but not least, check out this purple pepper – never seen in my life before!

Good Pig Farm

The next stop was at Olsburg, where we met Craig and Amy Good, who have been doing pig farming since 1975. They made a great team – Amy kept the books while Craig did outside work. Most of the pork that they raised on their farm is being sold to Heritage Foods, who distribute them to restaurants.

We learned from them how pig breeding and farming are done. It was a great opportunity to see the pigs at the various stages of their life. Also, I learned that raising animals was just like taking care of babies. We were asked to wear booties to keep our germs away and protect the pigs.

Learn some fun facts about pigs.

- Boar – Intact pig.

- Barrows – Castrated pig.

- Gilt – Female pigs when they are young.

- Sows – Female pigs once they are bred. A sow will have 5 litters in 2 years, with about 9-10 pigs in each litter.

- Pork meat is evaluated based on Minolta, and the higher the Minolta score, the better it is.

We also got an opportunity to meet Valerie – this talented young chef who runs a catering company called the fork in the road. Read about her amazing story here. She brought in lunch and everything she made was so so good that I forgot to take pictures! I enjoyed having roasted vegetables, sweet potatoes, and risotto (the best I’ve ever had). Thanks, Valerie for the scrumptious meal and also for sharing how you repurpose it so that there is zero wastage.

Liquid Art Winery

Do you know what a Vintner is? A vintner or winemaker is someone who is engaged in winemaking. Honest confession – I hadn’t heard the term vintner before I met David and Dani Tegtmeier from Liquid Art Winery.

David fell in love with the science and art of winemaking when he was 15 and decided he wanted to be a winemaker. He along with his wife Dani started working on their dream of building a winery in 2014. Construction began in 2015 and now they have a full production winery, a tasting room and an event center that accommodates up to 375 people.

My takeaway from this visit was – David dreamt of owning a winery when he was 15. Though his family was skeptical, he continued to pursue his dream. I was awestruck by his dedication towards the craft – how he and Dani planned for it in college by picking the right courses, worked in the industry first before starting on their own. It must have taken a great deal of patience and strategic planning to reach here. Such an awe-inspiring story.

Learn more about David and Dani’s story here and if you are in Kansas, click on this link to learn how you can get your hands on their wine and hard cider. It is one of a kind!

Day 2 – Rowantree Fiber Farms, Tiffany Cattle Company, and Baldwin Farms

Rowantree Fiber Farm

We kickstarted day two by visiting a fiber farm where they raise Pygora goats for their wool (or fiber). Rowantree Fiber Farm was started by the McGees (Collen and Mike) as a post-retirement venture. This visit was so much fun – we got an opportunity to see goats being sheared for their fiber, make yarn from fibers using spinning wheels, and also feed goats.

My takeaways from this visit

- Pygora goat fibers can be as soft as cashmere.

- Before the fiber extracted from the goat can be spun into yarn, it needs to be cleaned, sorted and washed. It is done at a temperature-controlled mill and takes about 5 days.

- Fibers are not only collected from sheep but also animals like buffalo and bunnies too!

To learn more about McGees, read this article and follow them on Facebook.

Tiffany Cattle Company

The next stop for the day was Tiffany Cattle Company – a finishing company where we met Shawn Tiffany one of the owners. If you didn’t know what a finishing company was, let me explain – it is the last stop before cattle are processed for meat. Shawn talked us through how the cattle are taken care of at a feedlot, what they are fed, how they are taken care of when they are sick. Stressed animals don’t do well in the market that is also one of the reasons why taking care of these animals humanely is so important.

Some takeaways

- About 3 million bushels of corn are needed every year to feed his cattle.

- What caught me by surprise was that the feedlot was not smelly. It was because they brought in wasps to take care of the flies. What a brilliant idea!

Baldwin Farms

The last stop of the day was at Baldwin Farms, where they grew sorghum, corn, and soybeans on their McPherson County farm. Kim Baldwin of Baldwin Farms, who is a teacher by profession had joined us on this bus tour and shared a lot of helpful information during this trip. I learned about how food-grade corn and non-food grade corn are different from each other. We also got to see the combine in action, and we made a quick trip to the grain elevators too! Grain elevators are facilities where crops are weighed and sampled to check for moisture content.

My takeaways from stopping over at Baldwin farms

- How technology plays a big role in agriculture. For example, there are application programs that help them understand how good the soil is in a particular area. This helps them program their seeders accordingly to spread more seeds in areas where the land is fertile.

- They have mostly drylands (depend on rainfall to water their crops), but some areas are irrigated (water is supplied) as well.

- Tilling involves digging, stirring, and overturning the soil to uproot weeds. Baldwin farms practice no-tilling (growing crops without disturbing the soil). This helps reduce soil erosion.

- How Adam and Kim diversified their business by growing and selling mushroom popcorn. Marketed as “Papa Baldy’s Popcorn”, it is available in several Kansas stores.

- Kansas is one of the topmost sorghum producers in the United States.

To learn more about Baldwins and the technology behind farming, read this article.

Day 3 – Wells’ Dairy and Leffler Farms

Wells’ Dairy

Our first stop of the day was Wells Dairy, where Heidi and Byron Wells welcomed us with some fresh fruits and yogurt. It was a great opportunity to understand the dairy farm operation. A lot of milk that they produce ends up as ice cream.

Here are my takeaways from this visit.

- Their day started at 3.00 AM when they would begin milking the cows (about 150 of them). They did it twice a day, and each cycle took about four hours from start to finish.

- They worked 365 days a year – no weekends or holidays off!

- During the entire milking process, the milk is untouched by humans. It goes from the pumps into a holding tank.

- Before the milk is shipped off to the processing facility in a tanker, it is tested for the presence of antibiotics twice – once by the Wells and the second time by the driver. If any contamination is found, the milk in the entire tanker has to be dumped, and the dairy farm that caused that contamination has to pay for it. That is why any cows who are sick and taking antibiotics are separated from the herd until they are well again.

Leffler Farms

Our final stop was at Leffler farms in Flint Hills where they raise soybeans, corn, wheat, and cattle. We were welcomed by Jacquelyne Leffler – a 4th generation farmer and a former athlete. She showed us her backgrounding lot where cattle are grown until they were ready to go to a feedlot like Tiffany’s for finishing. It was interesting to see that the lots had custom made gates to move cattle around efficiently.

Farming is a lot about smart decision-making – Jacquelyne shared how they purchased their cattle from Georgia because it is a lot cheaper than buying from Kansas.

For more on Jacquelyne’s story, check out this link.

That’s a wrap.

A huge thanks to Jancey Hall and Sheridan Wimmer for taking such good care of us on the tour. The experience is totally worth it and life-changing. I came back home with a renewed appreciation for our farmers. Also, I concluded that farming is like running any small business – you have to strategize, plan your finances, use technology/analytics to help make decisions, diversify your income streams, and, last but not least, leverage teamwork to get things done.